|

Model |

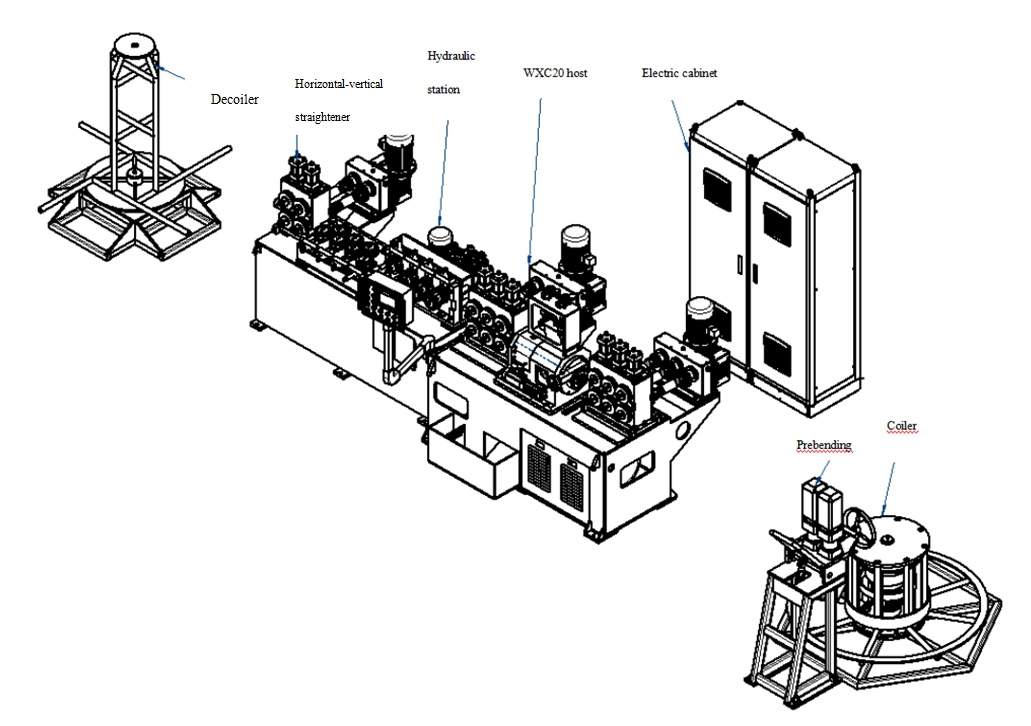

WXC20 coil to coil |

|

|

Raw Materials |

Diameter range(mm) |

Φ5.5~Φ20 |

|

Tensile strength σb(Mpa) |

≤900 |

|

|

Surface roughness |

≤HB320 |

|

|

Curvature requirement |

≤1. 5 ① (The coil should be cold drawn and rounded, no dead bending.) |

|

|

Diameter tolerance |

d-2-GB/T702-2004 |

|

|

Roundness |

≤50% of diameter tolerance |

|

|

Surface roughness(Ra) |

≤25mm |

|

|

Finished product |

single side cutting depth(mm)(peeling) |

0.25~1 |

|

Diameter range(mm)(peeling) |

Φ5~Φ19.5 |

|

|

Diameter tolerance(peeling) |

≤IT10(standard tolerance grade) |

|

|

Surface roughness(Ra)(peeling) |

≤6.3μm |

|

|

Roundness(mm) (peeling) |

≤0.03 |

|

|

Speed(Infinite speed adjustment m/min) |

1.0~20.0(Slow down for the materials with continuous chips, high strength, high hardness or big diameter. ) |

|

|

Rotating speed of cutter head(stepless speed adjustment)(r/min) |

900~2500 |

|

|

Main motor power of peeling machine(kW) |

22 |

|

|

Feeding motor of peeling machine(kW) |

3 X2 |

|

|

Vertical&horizontal straightener motor power(kW) |

3 |

|

|

servo motor of pre-bending machine(kW) |

1.5 |

|