Application fields

Bright bars

Nonferrous metals (copper/titanium/magnesium/aluminium)

Fastener industry

Automotive parts

Spring industry

Hydraulic pressure industry

Bearing manufacturing industry

Mechanical processing

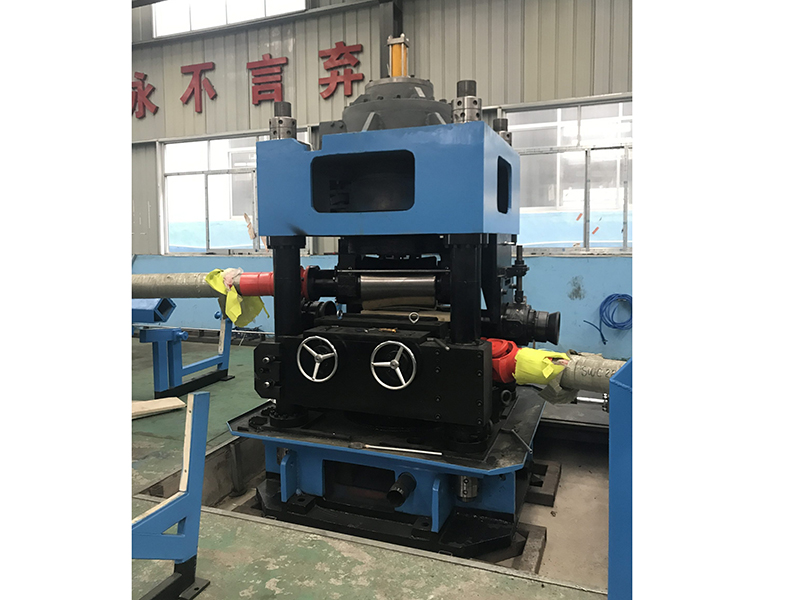

An Introduction to Straightening Machine

2-roll straightening machine is mainly used to straighten bended and distorted metal rods or pipes with guaranteed wall thickness with high efficiency. It can process both nonferrous metal or non-metal rod materials. 2-roll straightening machine and peeling machine can be combined to be a connected unit. If straightness of raw materials is above 1.5mm/m, pre-straightening shall be used before peeling.

There are 3 structures of 2-roll straightening machine : two-beam and four-column, pre-stressed type and frame type. After straightening, straightness of finished products can achieve 0.25~0.4mm/m. Surface roughness is less than 1 μm. The transportation devices have both manual and automatic types.

|

Model

|

Input Dia

|

Length

|

Feeding Speed

|

Surface Roughness

|

Straightness

|

Spindle Motor

|

Total Capacity

|

|

JY20Z

|

ф5-ф20mm

|

≥2000mm

|

2-30m/min

|

Ra≤0.8

|

≤0.25mm/m

|

2×7.5KW

|

18KW

|

|

JY40Z

|

ф8-ф40mm

|

≥2000mm

|

2-30m/min

|

Ra≤0.8

|

≤0.25mm/m

|

2×22KW

|

47KW

|

|

JY60Z

|

ф10-ф60mm

|

≥2000mm

|

2-30m/min

|

Ra≤0.8

|

≤0.25mm/m

|

2×37KW/55KW

|

90/100KW

|

|

JY80Z

|

ф20-ф80mm

|

≥2000mm

|

2-20m/min

|

Ra≤0.8

|

≤0.25mm/m

|

2×55KW/75KW

|

125/170KW

|

|

JY100Z

|

ф25-ф100mm

|

≥3000mm

|

2-15m/min

|

Ra≤0.8

|

≤0.25mm/m

|

2×75KW

|

170KW

|

|

JY130Z

|

ф35-ф130mm

|

≥3000mm

|

2-15m/min

|

Ra≤0.8

|

≤0.25mm/m

|

2×90KW

|

200KW

|

|

JY160Z

|

ф40-ф160mm

|

≥3000mm

|

1-10m/min

|

Ra≤0.8

|

≤0.25mm/m

|

2×132KW

|

280KW

|

|

JY200Z

|

ф60-ф200mm

|

≥3000mm

|

1-10m/min

|

Ra≤0.8

|

≤0.25mm/m

|

2×185KW

|

410KW

|

Strengths & Metrics

Optimized straightening effect, applicable to high strength materials

Pre-set angle of straightening rolls; Hyperbola of top and bottom uneven rolls guarantees linear friction between straightening rolls and rods

Infinite variable speed is adopted to adjust speed steadily.

Cooling lubricating extends working life of straightening rolls

Straightening rolls are installed vertically with greater straightening force and is in favour of maintenance

Parameter table

| Model | JY100Z | |||

| Workpiece required | Diameter range (mm) (non-) | Tensile strength σb≤450(Mpa) | Φ25≤d≤Φ100(L ≥2000) | |

| Tensile strength σb≤1000 | Φ25≤d≤Φ90(L ≥2000) | |||

| Surface hardness | ≤HB380(≤HRC42) | |||

| Straightness | ≤3 | |||

| Diameter tolerance | ≤IT10 | |||

| Roundness | d≤50 | ≤ 50% of diameter tolerance | ||

| 50<d≤80 | ≤ 65% of diameter tolerance | |||

| d>80 | ≤ 70% of diameter tolerance | |||

| Surface roughness | ≤3.2~6.3mm | |||

| Finished product | Straightness | ≤0.3 | ||

| Diameter tolerance | ≤IT8 | |||

| Surface roughness (Ra) | ≤0.8μm | |||

| Quantity of roll | 2 | |||

| Roll diameter (mm) | Φ380 | |||

| Straightening speed (infinite variable speed) | 2~15(m/min) | |||

| Main motor power (kW) | 75X2 | |||

| Lift motor power (kW) | 4 | |||

| Dimensions (m)(reference ) | Host machine 8.1X3.1X3.6 | |||

| Weight (t)(reference ) | Host machine 26.2 | |||

| Total capacity (kW)(reference ) | 170 | |||

| Source of compressed air (Prepared by the user) | 0.5~0.8MPa、1.8m3/min、with second grade oil-water separator | |||